Quality assurance and testing

Our committed Quality Assurance team certifies that strict and consistent quality control procedures and methods are implemented in all our offshore and domestic facilities in order to maintain the highest standards of quality in our products.

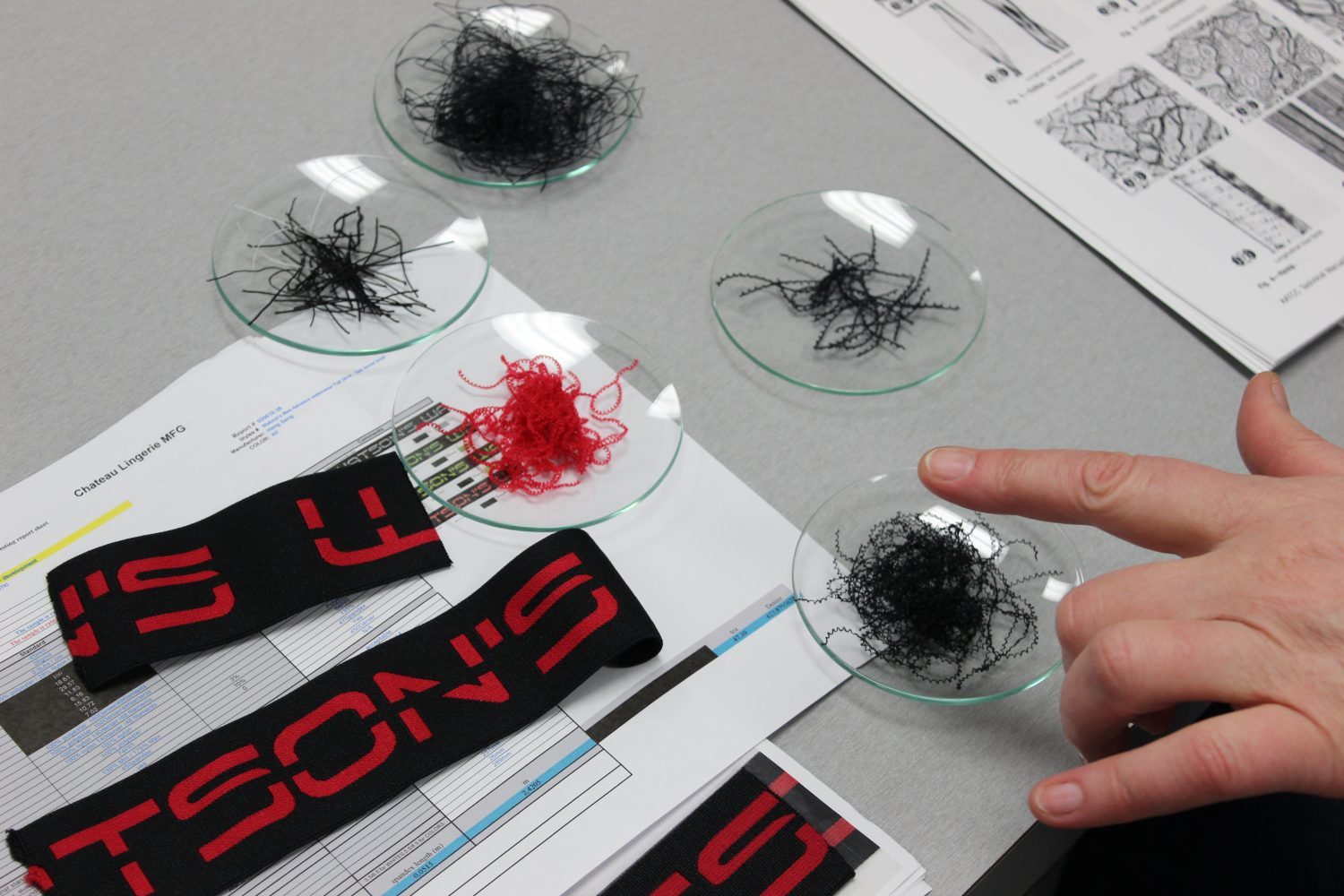

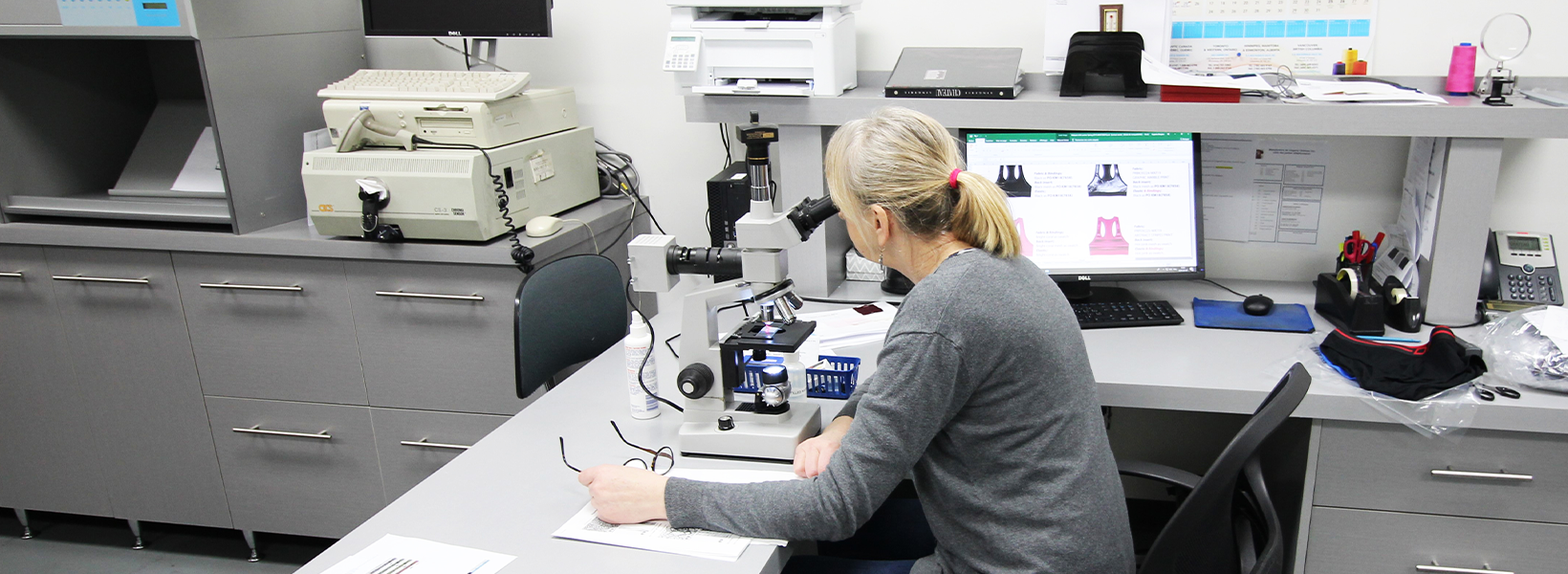

We use industry accredited testing equipment and standards in our own domestic textile lab and third-party testing facilities (including Bureau Veritas, Intertek and SGS) to assure that our products exceed the quality standards of the industry . Testing methods from the AATCC, A.S.T.M. and ISO are consistently applied from yarn to finished product.

- Fabric durability

- Strength

- Colorfastness

- pH level

- Dimensional stability

- Heat retention

- Wicking

- Antimicrobial effectiveness

- Fiber content

- Far infrared

- Color assessment

Waistbands and trims:

- Torque

- Elasticity

- Modulus

- Durability (10,000 cycle flex test)

- Fiber content

- Weave structure

- Deformation

- Colorfastness

- Fiber and yarn analysis

Packaging:

- Cold storage resistance

- Ink transfer

- Material quality & grade

- Seam strength

- Coating & finishing

- Phenolic yellowing

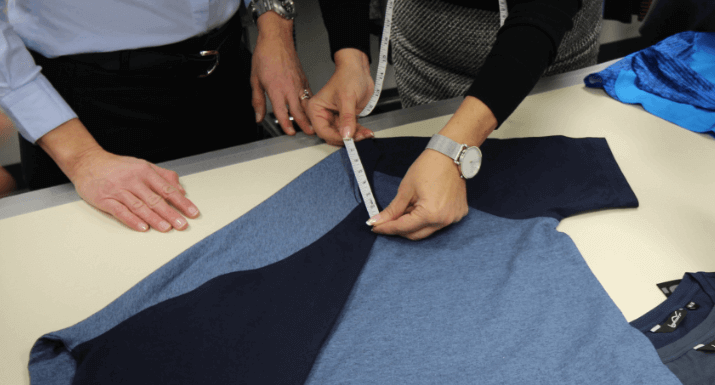

Quality Control & Inspection

Our own offshore quality assurance team inspects 100% of both our in-line and completed production lots using high level industry AQL sampling methods.

Our domestic QA team inspects each and every shipment received in our Distribution Center using the same rigorous procedures.